Any manufacturer understands the importance of end-product reliability. Failure of the assembly at the customer’s end leads to not only extra costs in rework, but also loss of brand equity. Know how LOCTITE products can overcome manufacturing challenges that conventional methods can’t.

Joining dissimilar material

Challenge

Conventional methods like welding are only able to bond similar materials. LOCTITE allows you the design freedom to use different types of materials and make your assemblies truly LIMITLESS. Electric motors are prime examples where LOCTITE is used to bond ferrite magnets to zinc dichromatic coated steel

Stress Distribution

Challenge

LOCTITE adhesives distribute the stress evenly over the entire bond area, whereas with conventional methods like nuts and bolts or riveting the stress is concentrated on areas of contact. As a result, with LOCTITE you get greater strength and less stress fracturing than you would with mechanical fasteners.

Assembly Protection

Challenge

In addition to bonding LOCTITE adhesives also provide a 100% seal. This keeps contaminants from the reaching the inside of the assembly or device. It also prevents leakage of fluids or gasses from inside the device.

Aesthetic Improvement

Challenge

Aesthetics is another reason why one should choose LOCTITE. Our products eliminate weld burns or protruding fasteners. Therefore, you have a much more aesthetically pleasing smoother surface on the exterior.

Gap filling

Challenge

LOCTITE adhesives fill voids or imperfections in materials. Gap control is very important for alternative methods such as welding. Adhesives can bond through gaps in structural applications and achieve high strength final assemblies.

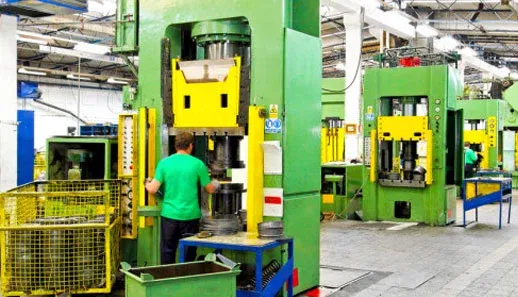

Process Automation

Challenge

Handling of adhesives can be easily automated through our wide range of mechanical and electronic solutions. This makes the process of using adhesives very clean and quick, resulting in low material wastage and a shorter cycle time.

Get a deeper understanding about minimizing downtime and increasing productivity in a plant

-

Solving manufacturing challenges with LOCTITE

Solving manufacturing challenges with LOCTITERead this infographic to know how LOCTITE can help you overcome some the most common manufacturing challenges.

Know More -

Value savings with LOCTITE

Value savings with LOCTITELOCTITE adhesives are one of the most cost-effective ways to manufacture adhesives and maintain plant equipment. Know how LOCTITE adhesives compare against some of the commonly used conventional methods

Know More

BEST SELLER PRODUCTS

Sorry, this can not be processed now.

Product Recommender

Product Recommender  Value Calculator

Value Calculator  Track Order

Track Order

1800 123 1922

1800 123 1922

Maintenance

of Pumps

Maintenance

of Pumps

Maintenance

of Electric

Motor

Maintenance

of Electric

Motor

Maintenance

of Gearbox

Maintenance

of Gearbox

Maintenance

of Compressor

Maintenance

of Compressor