situation

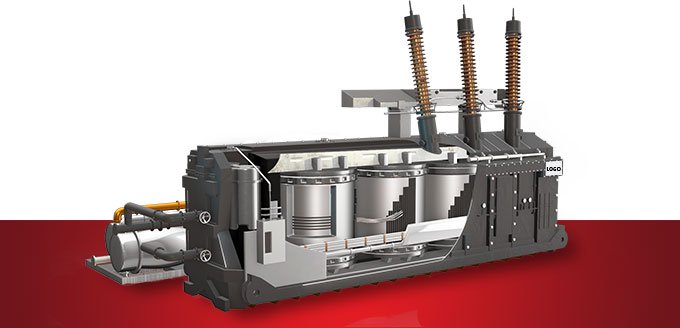

A transformer manufacturer was looking for a solution to seal weld porosities as it led to the seeping out of the transformer oil and contamination of the soil. Porosity leaks also resulted in off-line repairs which resulted in increased repair costs and reduced production output.

Conventional methods and drawbacks

Welding over leaking weld beads did not stop the leak and needed high labor cost to drain, clean, grind and weld over the identified porosity leaks.

loctite solution

LOCTITE 290 is applied to the porosity with a brush and shows results within minutes.

LOCTITE Increasing Transformer Reliability

Product Recommender

Product Recommender  Value Calculator

Value Calculator  Track Order

Track Order

Offers

Offers  1800 123 1922

1800 123 1922

Maintenance

of Pumps

Maintenance

of Pumps

Maintenance

of Electric

Motor

Maintenance

of Electric

Motor

Maintenance

of Gearbox

Maintenance

of Gearbox

Maintenance

of Compressor

Maintenance

of Compressor